Main activities

Solutions for 3D modeling, stress analysis, laser scanning, digital twin and customized solutions.

An advanced environment for creating work packages for industrial projects

Our Company is able to provide highly professional project management and control services. The software primarily used for these activities is Oracle Primavera, Hexagon Ecosys and Microsoft Project.

Software

E3D, Smart 3D, CADWorx plant, OpenPLANT, AutoPLANT, Microstation.

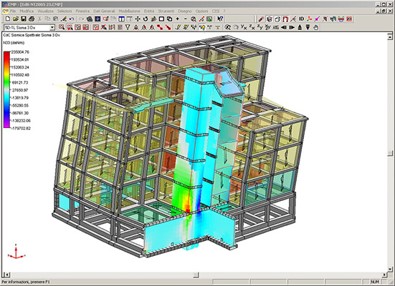

CAESAR II, AUTOPIPE, Autopipe Vessel, FEA Tools, etc.

Z+F Laser Control Office v 9.2, Leica Cyclone 9.4.0, Gexcel JRC Reconstructor, Autodesk AEC Collection 2021 Agisoft Photoscan, Agisoft Metashape professional , Clearedge Edgewise, PointCAB

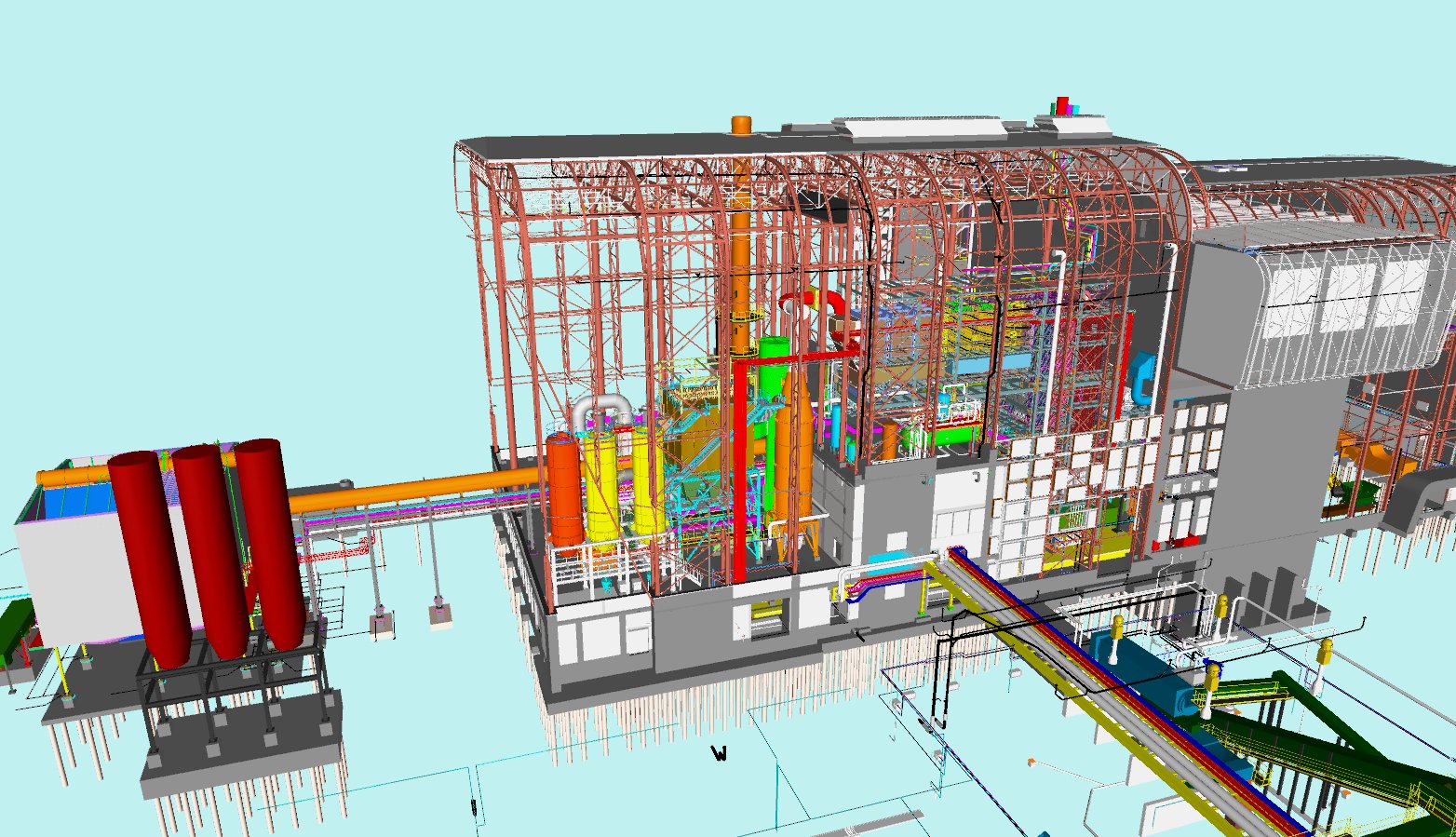

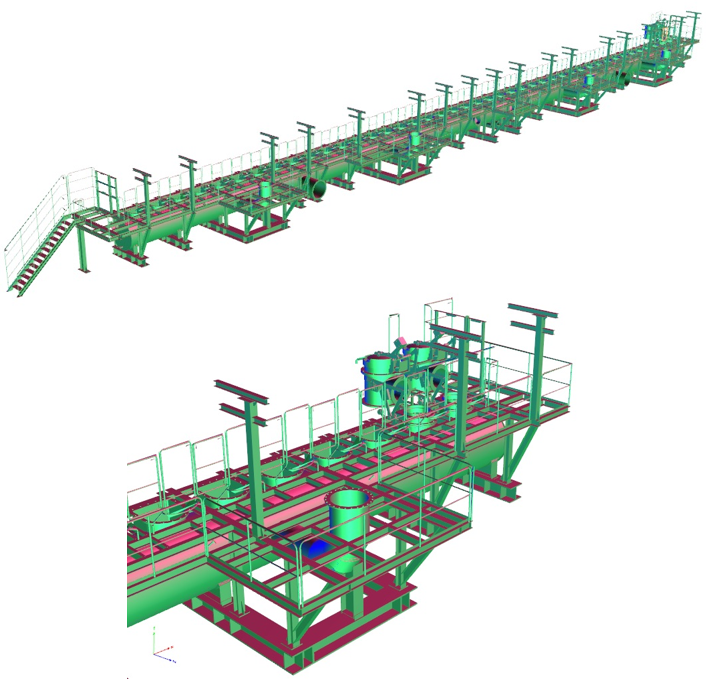

3D plant engineering

Our team is composed of professionals with twenty years experience in the field of plant design (2D / 3D) and analysis (stress analysis) and is able to operate in the following sectors: petrochemical, iron and steel, shipbuilding, energy, water treatment, transport, etc.; we can use the most popular software on the market, such as: Autocad®, Inventor®, Smart 3D®, CADWorx®, OpenPlant ®, AutoPLANT ®, E3D/PDMS ®, ESApro, etc. The team supports Customers throughout the project cycle, from layout viability to the preparation of shop drawings for isometrics, supports and steel ancillary structures. Among the plants we have developed we are particularly proud of our work on heating oil refinery furnaces. For such projects we have also carried out stress analysis on internal and external lines, the piping assembly development, isometrics, bills of materials and the specifications of the supports for burner supply lines, product input lines, transfer lines and decoking lines.Mechanical engineering

Our experience in the machinery and furnaces sector focuses in particular on the following activities:

Steel structure and civil design

Civil engineering is a professional engineering discipline that deals with the design, construction, and maintenance of the physical and naturally built environment, including works such as roads, bridges, canals, dams, airports, sewerage systems, pipelines, and railways.[ Steel design, or more specifically, structural steel design, is an area of knowledge of structural engineering used to design steel structures. The structures can range from schools to homes to bridges. Our experience in the discipline focuses mainly on the following activities, we are able to provide structural design with Tekla ®, Revit ®, Aztec ®, CADWorx ® Structural, etc. The main activities that the department carries out are as follows:Piping material spec’s

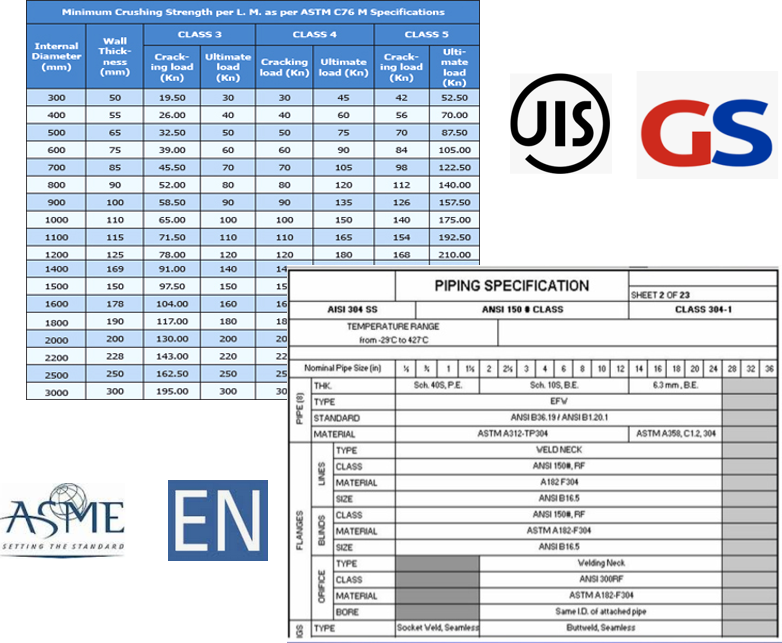

Piping class or Pipe Class is a document that specifies the type of the components such as a type of pipe, schedule, material, flange ratings, branch types, valve types and valve trim material, gasket and all the other components specific requirements to be used for different fluids under different operating conditions in a plant. Our team is able to prepare piping classes for the most common three-dimensional CAD design systems on the market, for Puma5® piping materials management or in .xls format for “manual” use or for import into other systems. We are able to develop piping material specifications taking into account ASME (American), EU (European), JIS (Japanese) and GOST (Russian) regulation requirements.

Fire prevention system design

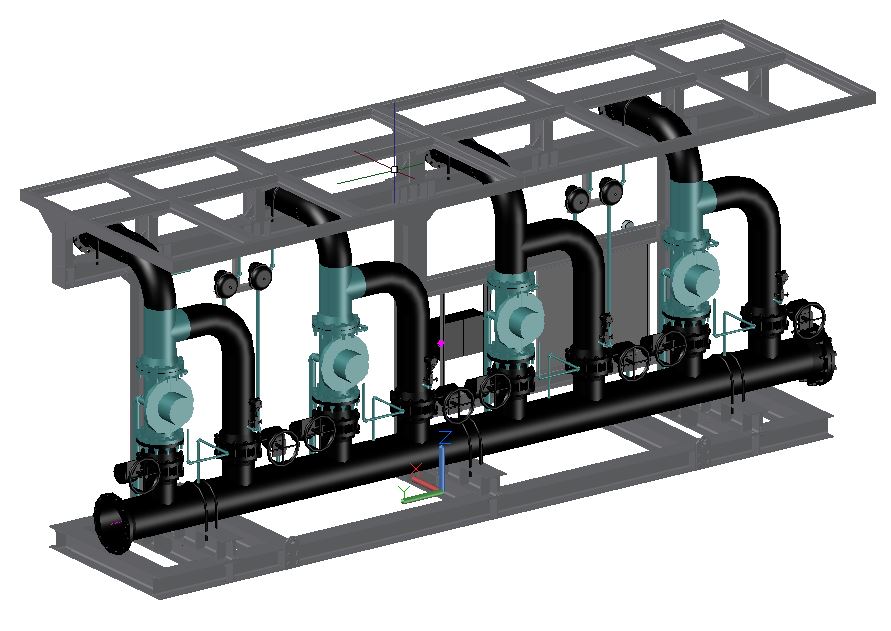

The fire extinguishing system is a set of electronic, electromechanical, hydraulic or other equipment that aims to prevent or extinguish a fire and raise the alarm. Based on the type of danger, ie the type of material that could catch fire, different systems can be designed. In the field of fire prevention design we are able to develop all the engineering part for the most important types of spread through the market system. For each type of system we can provide relative reports to identify the risks in the various environments, design the most suitable type of system and provide the necessary analyzes for the sizing of the plants. The calculations and analyzes are developed with software of primary importance at an international level (Pipenet Sunrise, etc.) and in accordance with various regulations, including the NFPA.E&I Engineering

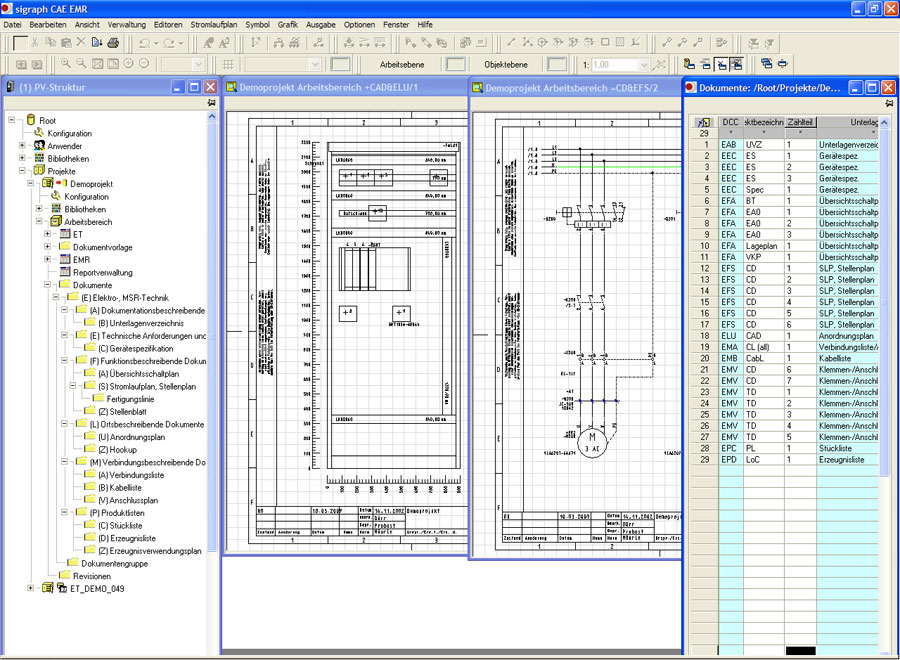

Our electrical engineering department is able to perform the following main activities: